Material and Manufacturing Process of Wooden Formwork

High-Quality Timber Selection

Wooden formwork is primarily made from high-quality timbers such as pine, poplar, and eucalyptus. These woods are lightweight, strong, and easy to process, ensuring the durability and stability of the formwork.

Precision Manufacturing Process

The production process of wooden formwork includes the following steps:

1. Cutting: Timber is precisely cut according to design specifications.

2. Assembly: The cut boards are assembled to form the required structure.

3. Finishing: The assembled formwork is smoothed to ensure a flat, even surface.

4. Painting: A coating is applied to enhance water and corrosion resistance.

Key Advantages of Wooden Formwork

- Easy to Process

Wooden formwork is highly flexible in processing, making it adaptable to various construction needs. It can be customized and adjusted to meet specific requirements.

- Good Flexibility

Wooden formwork has excellent flexibility, adapting to different construction environments and conditions while withstanding certain pressures and impacts.

- Wide Panels with Fewer Joints

The formwork panels are wide, reducing the number of joints, which minimizes the risk of leakage and seam issues during pouring, improving the overall quality of the concrete.

- Smooth Surface and Easy Demolding

The finely processed surface ensures smoothness and prevents sticking during demolding, facilitating construction.

- Cost-Effective

Compared to other types of formwork, wooden formwork is relatively affordable, making it a cost-efficient choice for large-scale projects.

Maintenance and Care

- Timely Cleaning: Clean the formwork surface after demolding, avoiding hard objects that could scratch the surface.

- Proper Storage: After each use, store the formwork on a flat surface with wooden blocks to avoid direct contact with the ground.

- Ventilation and Drying: For long-term storage, ensure proper ventilation to prevent exposure to sunlight and rain. Use waterproof covers and conduct regular inspections.

Specifications and Technical Parameters of Wooden Formwork

High-Quality Plywood

| Inner Diameter | Thickness | Standard Height | Quantity |

| 250-550mm | 15mm | 3000mm | 2 |

| 600-1250mm | 18mm | 3000mm | 2 |

| 1300-1550mm | 22mm | 3000mm | 2 |

| 1600-4200mm | 22mm | 2400mm | 4-10 |

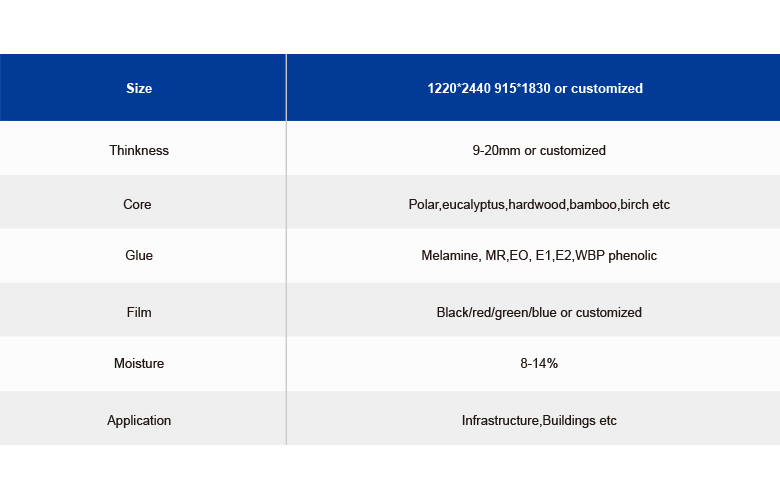

Film-Faced Plywood

| Size | 1220mm x 2440mm |

| Thickness | 12/15/18mm |

| Glue | MR, E1, E2, WBP |

| Core Material | Poplar, Hardwood |

| Surface | Polypropylene Layer |

| Moisture Content | 7%-13% |

| Grade | A, B |

| Application | Furniture, Construction, Decoration |

Factory Manufacturing Process Display

A display of the key steps in the wooden formwork production process highlights its efficient and professional processing capabilities.

Viktor Remel

Viktor Remel