Materials and Characteristics of Steel Structures

Main Types of Materials

Steel structures mainly use carbon structural steel and low-alloy structural steel. These materials offer high strength, good toughness, and excellent processing and welding performance, making steel structures easy to manufacture and assemble on-site or in a factory.

Durability and Corrosion Resistance of Steel

Corrosion-treated steel effectively prevents rusting, especially in harsh environments like marine engineering and chemical plants. Galvanizing or anti-corrosion coatings are commonly used to extend service life.

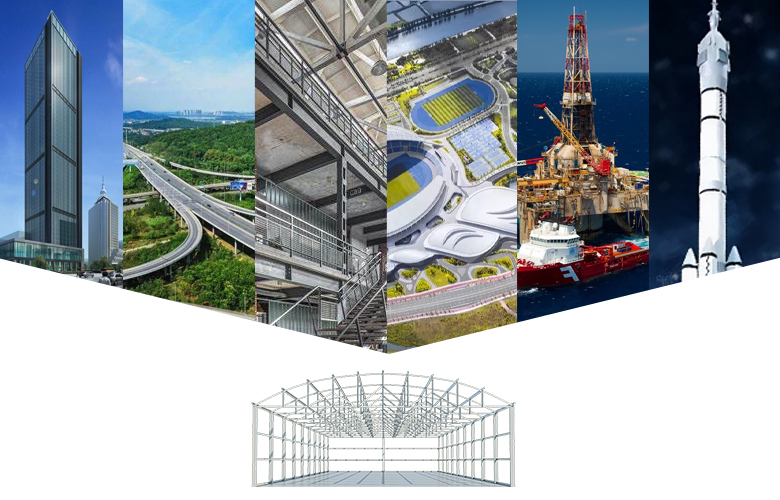

Broad Applications of Steel Structures

Due to their high strength, low weight, and adaptability, steel structures are widely used in various architectural and engineering fields:

High-Rise Buildings

Ideal for skyscraper frameworks, steel structures are lighter than traditional concrete, reducing foundation load and providing earthquake and wind resistance.

Bridges and Highway Facilities

Steel structures are common in bridges, overpasses, and tunnels, offering reliable support for long spans and excellent fatigue resistance.

Industrial Buildings

Steel structures are extensively used in factories, warehouses, and workshops, providing efficient support for large spaces and spans required in industrial settings.

Sports Arenas and Exhibition Centers

Large arenas and exhibition centers often use steel structures, especially space frames or grids, to create column-free, expansive spaces that improve sightlines and space utilization.

Marine Engineering

Steel structures are widely used in offshore oil platforms, docks, and marine projects. Their corrosion resistance and structural stability make them suitable for marine environments and resistant to waves and tides.

Aerospace and High-Tech Facilities

The lightweight, high-strength properties of steel make it the preferred material in aerospace, satellite launch bases, and research centers.

Advantages of Steel Structures

Lightweight and High Strength

Steel has a high strength-to-weight ratio, allowing for smaller sections and lighter weight, making steel structures ideal for long-span and high-rise buildings.

Short Construction Period and Easy Installation

Steel components are typically manufactured in factories and assembled on-site, greatly reducing construction time, especially for large industrial projects.

Excellent Seismic Performance

The ductility and seismic resistance of steel make it suitable for buildings in earthquake-prone areas, making it a common choice for modern high-rise and large-scale projects.

Efficient Industrialized Production

Steel structure components are produced, processed, and installed with a high degree of mechanization, improving efficiency, reducing labor costs, and enabling mass production.

Environmentally Friendly and Sustainable

Steel structures generate minimal waste during construction and demolition, and steel is recyclable, aligning with green building and sustainable development principles. Compared to traditional buildings, steel construction has a lower environmental impact.

Extended Service Life with Fire and Corrosion Protection

Steel structures can be treated for fire and corrosion resistance, especially in high-temperature, high-humidity environments, through fireproof coatings and anti-corrosion treatments, enhancing suitability for diverse applications.

Types of Steel Structure Systems

Frame Structures

Commonly used in multi-story or high-rise buildings, providing good lateral force resistance, ideal for tall buildings.

Grid Structures

Grid structures are formed by connecting multiple rods, suitable for large-span buildings like exhibition halls and stadiums, combining strength with reduced weight.

Suspension Structures

Primarily used in bridge construction, suspension structures offer excellent wind resistance, enabling long spans with a visually appealing design.

Composite Structures

Combining steel and concrete, composite structures utilize steel's high strength and concrete's fire resistance, making them suitable for high-rise buildings and bridges.

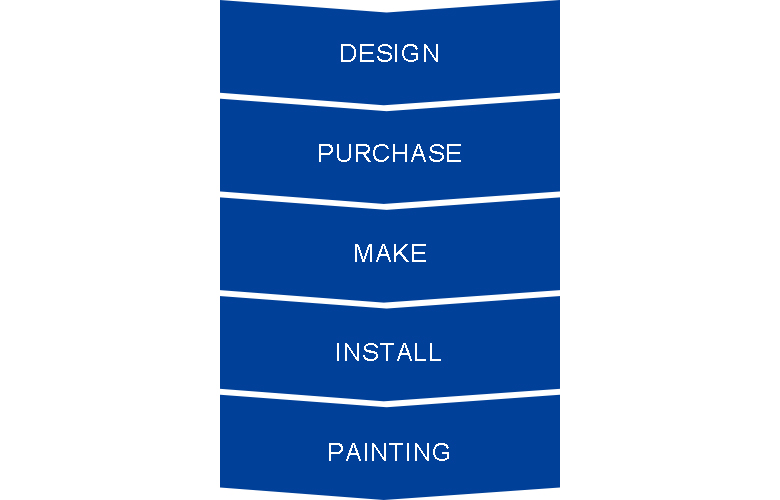

Construction Process of Steel Structure Engineering

Design and Drawing Confirmation

Detailed structural design and drawing confirmation are required before project initiation to ensure safety and feasibility.

Material Procurement and Quality Control

Steel meeting standards is procured and quality-checked for strength, corrosion resistance, etc., before production.

Factory Prefabrication and Processing

Steel components are cut, welded, and processed in the factory, then transported to the construction site for assembly.

On-Site Installation and Assembly

Components are assembled and connected on-site using lifting equipment, with each stage undergoing safety checks to ensure quality.

Coating and Corrosion Treatment

After installation, steel components receive coatings and corrosion treatments to enhance fire and corrosion resistance.

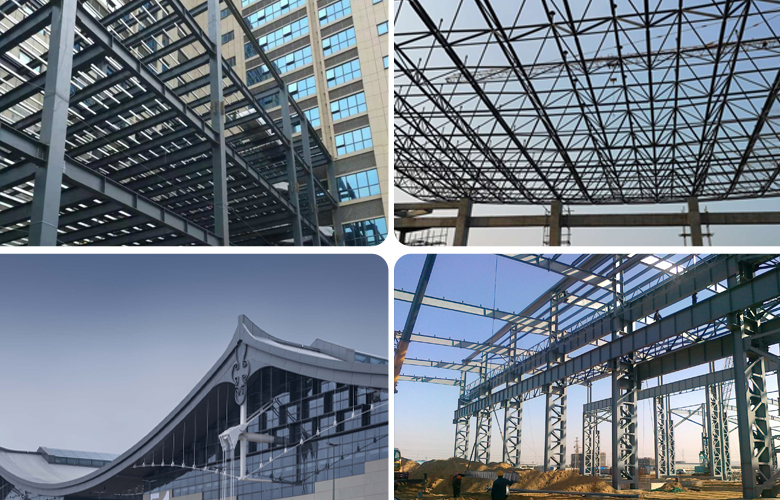

Typical Application Case Images of Steel Structures

Images show steel structures in high-rise buildings, bridges, and industrial buildings, helping you visualize the advantages and practical applications of steel structures.

Viktor Remel

Viktor Remel