Material and Manufacturing Process of Aluminum Formwork

High-Quality 6061-T6 Aluminum Alloy

Aluminum formwork is made from 6061-T6 aluminum alloy, a high-strength material known for its excellent corrosion resistance and lightweight properties. This makes it highly suitable for construction projects. The durability and reusability of aluminum alloy make it an economical and environmentally friendly choice for building materials.

Precision Manufacturing Process

Aluminum formwork is processed using machining and welding techniques. Machining ensures precise dimensions, meeting stringent construction standards, while welding enhances the strength of connections, ensuring stability and safety during construction.

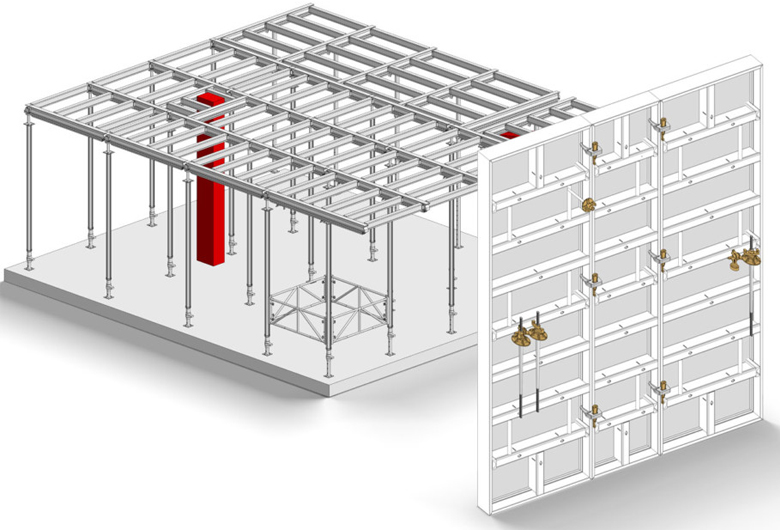

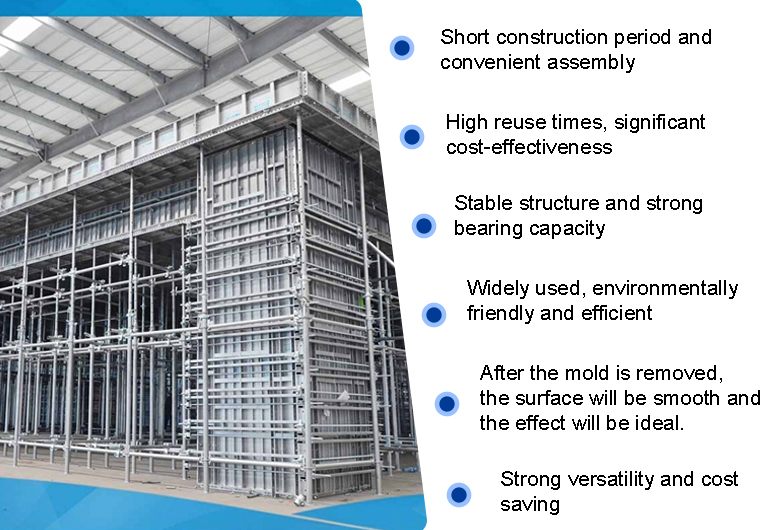

Key Advantages of Aluminum Formwork

- Short construction cycles with easy assembly

- High reusability, providing significant cost benefits

- Stable structure with strong load-bearing capacity

- Wide range of applications, environmentally efficient

- Smooth surface after demolding, delivering ideal results

- Versatile, helping save costs

Specifications and Technical Parameters of Aluminum Formwork

| Parameter | Description |

| Material | 6061-T6 Aluminum Alloy |

| Thickness | Customizable based on project requirements |

| Surface Treatment | Oxidation coating treatment |

| Load Capacity | Suitable for large-scale construction needs |

| Applications | High-rise buildings, residential projects, bridges, underground works, etc. |

Typical Applications of Aluminum Formwork

High-Rise Buildings and Residential Projects

In high-rise buildings and residential projects, aluminum formwork serves as a primary support material, providing a flat and stable structure for concrete pouring, improving construction quality and reducing project timelines.

Bridges and Highway Engineering

Aluminum formwork is ideal for bridge and highway infrastructure construction. Its lightweight and high-strength properties make it convenient and safe to use, particularly for large-span structures.

Underground Projects and Hydraulic Facilities

Aluminum formwork is well-suited for underground engineering, offering excellent corrosion and wear resistance. It is widely used in the casting and support of hydraulic facilities.

Aluminum Formwork Application Case Studies

- Case Study 1: Use of aluminum formwork in high-rise construction, showcasing its fast and convenient assembly characteristics.

- Case Study 2: Application of aluminum formwork in bridge engineering, demonstrating its outstanding load-bearing capacity and construction quality.

Viktor Remel

Viktor Remel